Whiskey Still Pro Shop Blogs

1 gallon

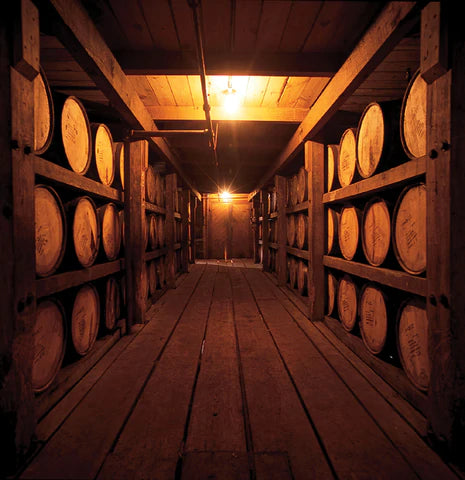

The Science of Whiskey Barrels

There has been a recent trend in the small, independently brewed liquor makers’ community. While men and women all over the world have entrusted their palates to fine liquor makers from establishe...

copper

How Much Alcohol Will My Whiskey Still Make?

Although every copper moonshine still is different, many distillers start with a basic question like “how much moonshine will my still produce?” or “how much will I get out of my 5 gallon whiskey s...

copper

Distilling and Temperature Control

Temperature control is important when distilling. Don't lie down on the job.

Distilling alcohol at home is an exciting process that requires skill and diligence. If you want to be great at it, be a...

chemistry

Why the Best Whiskey Stills are Copper

There are many high-quality whiskey stills for sale online - some already built and some delivered in assembly kits for you to put together yourself. For many reasons, the best stills are copper, w...