Whiskey Still Pro Shop Blogs

distilling

The Truth About US Law and Distilling Alcohol at Home

Historically, people have distilled grappas, spirits, water, and essential oils in their homes for centuries. The copper stills we have come to know as “whiskey stills” or “moonshine stills” are ol...

Bain-Marie still

How to “Cut” your Alcohol Distilling Run

Alcohol distillation is an ancient process that is both an art and a science. It’s easy, but not as easy as simply turning it on and watching it go. Diligent distillers know that you have to keep a...

distilling

How to Distill Whiskey and Moonshine

There are a few methods of distilling, but the most common include pot boiling and steam distillation. The most common thing distilled around the world is water - which is used in medical facilitie...

copper

Distilling and Temperature Control

Temperature control is important when distilling. Don't lie down on the job.

Distilling alcohol at home is an exciting process that requires skill and diligence. If you want to be great at it, be a...

distilling

Easy DIY Flour Paste for Your Copper Still

Distilling alcohol can be fun, but it can also be dangerous. One of the most important considerations to make is that when you heat alcohol, you deal with flammable alcohol vapors. In addition to m...

column still

7 Safety Tips for Distilling at Home

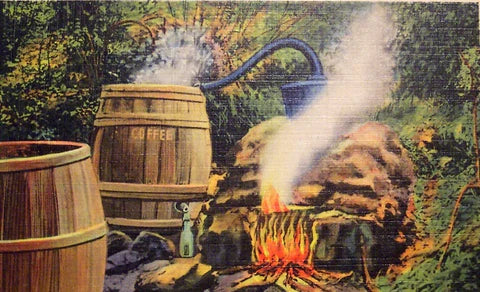

There's always a right way, and a wrong way, to go about distilling at home"Making Moonshine in Kentucky"

Moonshiners know that there will always be some safety hazards when working with a heat so...

column still

Parts of a Moonshine Still

Becoming an expert at distilling your own alcohol, water, or essential oils at home means that you need to become familiar with every part of your copper still. Moonshiners run into all kinds of pr...

clean copper

How to Clean a Copper Still Inside and Out

Copper is a durable, rich material that will last you decades if cleaned and cared for properly. It’s inexpensive to clean your copper still, but it does take a little time and effort on a regular ...