Whiskey Still Pro Shop Blogs

aging

The Age-Old Secrets of Aging Spirits at Home

In the hush of your home distillery, a clear spirit begins its journey to complexity. This transformation is the heart of the aging process, where time weaves its magic, infusing the liquor with n...

“Craft” Whiskey, What Is It? – 6 Things to Know Before You Start Distilling

If you’re a true enthusiast, you’ve probably heard the word “craft” used to describe whiskey. But what makes a whiskey “craft”? How do you tell “craft” whiskey apart from regular old whiskey? We’re...

1 gallon

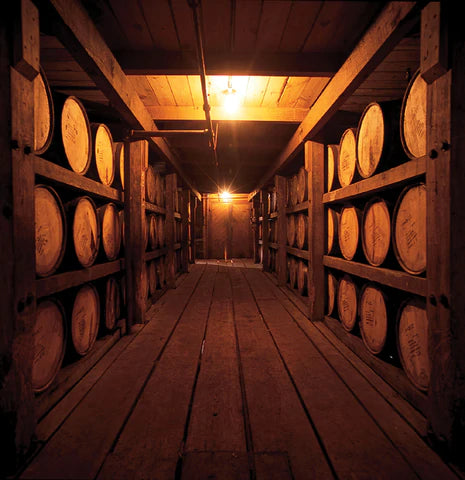

The Science of Whiskey Barrels

There has been a recent trend in the small, independently brewed liquor makers’ community. While men and women all over the world have entrusted their palates to fine liquor makers from establishe...

column still

What is a Conical Column Whiskey Still and Why is it a Premium Design?

One of the most unique and efficient copper still designs is the “Kentucky” premium design - an 8 gallon moonshine still with a conical column that increases the “reflux” that occurs during your di...

copper

How Much Alcohol Will My Whiskey Still Make?

Although every copper moonshine still is different, many distillers start with a basic question like “how much moonshine will my still produce?” or “how much will I get out of my 5 gallon whiskey s...

distilling

The Truth About US Law and Distilling Alcohol at Home

Historically, people have distilled grappas, spirits, water, and essential oils in their homes for centuries. The copper stills we have come to know as “whiskey stills” or “moonshine stills” are ol...

how to

Basic Moonshine Mash Recipe

“Moonshine” is distilled from the fermented sugar of a malt grains like oats, cornmeal, or wheat. A strong alcohol, the recipe for moonshine is very basic, which is why it has been popular througho...

Bain-Marie still

How to “Cut” your Alcohol Distilling Run

Alcohol distillation is an ancient process that is both an art and a science. It’s easy, but not as easy as simply turning it on and watching it go. Diligent distillers know that you have to keep a...

distilling

How to Distill Whiskey and Moonshine

There are a few methods of distilling, but the most common include pot boiling and steam distillation. The most common thing distilled around the world is water - which is used in medical facilitie...